Tag Archive for: PAT Testing

https://electricalinstallationservices.co.uk/wp-content/uploads/2022/11/PAT-test13amp-plug-with-label.jpg

400

495

Jeff Evans

https://electricalinstallationservices.co.uk/wp-content/uploads/2017/12/EIS-Logo-340-purple.png

Jeff Evans2022-11-25 11:44:512022-11-25 11:44:51Is PAT Testing Necessary?

https://electricalinstallationservices.co.uk/wp-content/uploads/2022/11/PAT-test13amp-plug-with-label.jpg

400

495

Jeff Evans

https://electricalinstallationservices.co.uk/wp-content/uploads/2017/12/EIS-Logo-340-purple.png

Jeff Evans2022-11-25 11:44:512022-11-25 11:44:51Is PAT Testing Necessary? https://electricalinstallationservices.co.uk/wp-content/uploads/2022/07/Commercial-PAT-Testing-1-scaled-e1659097258124.jpeg

202

300

Gary Crilly

https://electricalinstallationservices.co.uk/wp-content/uploads/2017/12/EIS-Logo-340-purple.png

Gary Crilly2022-07-29 14:52:122022-08-12 07:24:57Commercial PAT Testing

https://electricalinstallationservices.co.uk/wp-content/uploads/2022/07/Commercial-PAT-Testing-1-scaled-e1659097258124.jpeg

202

300

Gary Crilly

https://electricalinstallationservices.co.uk/wp-content/uploads/2017/12/EIS-Logo-340-purple.png

Gary Crilly2022-07-29 14:52:122022-08-12 07:24:57Commercial PAT Testing https://electricalinstallationservices.co.uk/wp-content/uploads/2021/02/PAT-Testing-Regulations-scaled-e1612343865277.jpeg

266

400

Gary Crilly

https://electricalinstallationservices.co.uk/wp-content/uploads/2017/12/EIS-Logo-340-purple.png

Gary Crilly2021-02-03 09:20:442024-06-21 10:49:03PAT Testing Regulations UK

https://electricalinstallationservices.co.uk/wp-content/uploads/2021/02/PAT-Testing-Regulations-scaled-e1612343865277.jpeg

266

400

Gary Crilly

https://electricalinstallationservices.co.uk/wp-content/uploads/2017/12/EIS-Logo-340-purple.png

Gary Crilly2021-02-03 09:20:442024-06-21 10:49:03PAT Testing Regulations UK

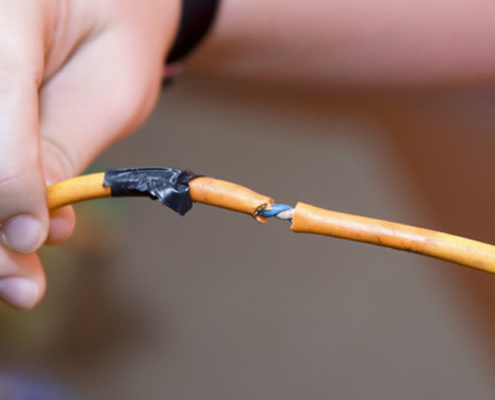

PAT Testing in the Workplace

A Quick Guide to PAT Testing for the Workplace

Electricity is…

What is PAT Testing?

What is Portable Appliance Testing?

Portable Appliance Testing…